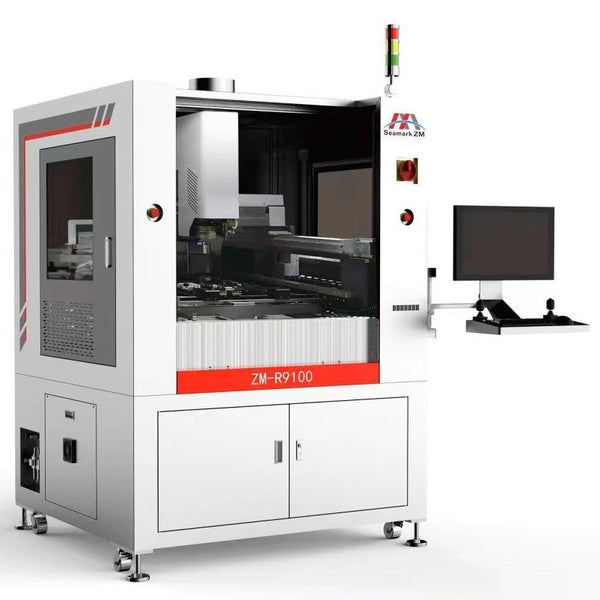

Automatic BGA & SMD Rework Station - Model ZM-R7880

ZM-R7880, it is an integrated desoldering and rework machine, combining solder removal,

disassembly, and welding functions into one for more convenient and intelligent repair

operations. It features a desoldering head and de-soldering head components, upper and

lower temperature zone control systems, upper and lower 200W high-definition camera

visual positioning systems, XYZR axis drive, equipped with a 19-inch high-definition LCD

monitor and a high-performance industrial computer. Supported by a multifunctional and

user-friendly operating system and a dedicated temperature controller, it can display 10

temperature curve segments simultaneously and has instant curve analysis capabilities. It can store multiple sets of temperature settings parameters, which can be switched at any time without the need for reconfiguration each time. additionally, the heating curves generated from each session are automatically recorded for future reference. The machine can be connected to external compressed air or nitrogen, and an optional external monitoring camera can be added for real-time monitoring of the rework process.

Non-contact Desoldering

The non-contact desoldering is achieved through the combined assistance of a precision

weighing sensor and real-time height monitoring via desoldering vacuum negative pressure, thereby reducing the risk of product damage, scrapping, and pad scratching during the desoldering process.

Rapid Programming of tin removal path

The equipment supports rapid Programming of tin removal paths by importing product CAD point maps. It also supports quick generation of tin removal paths through CCD photography collage without Gerber files. New product formula Programming is simple and straightforward.

Three Independent Preheating Platforms

Equipped with three independent preheating/heating platforms: upper de-soldering, upper desoldering, and lower preheating. All heating and preheating platforms and the desoldering head use closed-loop temperature control, ensuring stable and accurate overall temperature control.

Upper and Lower CCD Vision Systems

Equipped with two sets of cameras above and below, using self-developed control software and algorithms, the positioning accuracy and automation level are high. For reworking the

same PCB location, only the first alignment is needed, after which "one-click rework" can be performed.

Specifications and technical parameters ZM-R7880

1. Power: AC 207 to 250 Volts

2. Total Power: Max 5800W

3. Top heater power: 2000W

4. Bottom area heater power: 3300W

6. Mounting accuracy: ±0.025mm

7. Max PCB size: Max 450mm× 360.

8. BGA chip size: 5mm×5mm—60mm×60mm

All of our systems include 1 year parts warranty and lifetime technical support from our USA based locations.

List price includes 2-days for onsite set up and training within the USA.

Prices subject to change based on current tariff. Call for current pricing.

Call (530) 403-9103 for answers to your questions.